The automotive industry is currently tilting its gears to incorporate high-end manufacturing technologies, and it is worth noting that SLM (Selective Laser Melting) 3D printing services are at the heart of this shift. WHALE STONE 3D focuses on advanced SLM 3D printing technologies, which change the automotive industry for the better through high quality, fast turn-around, and personalization.

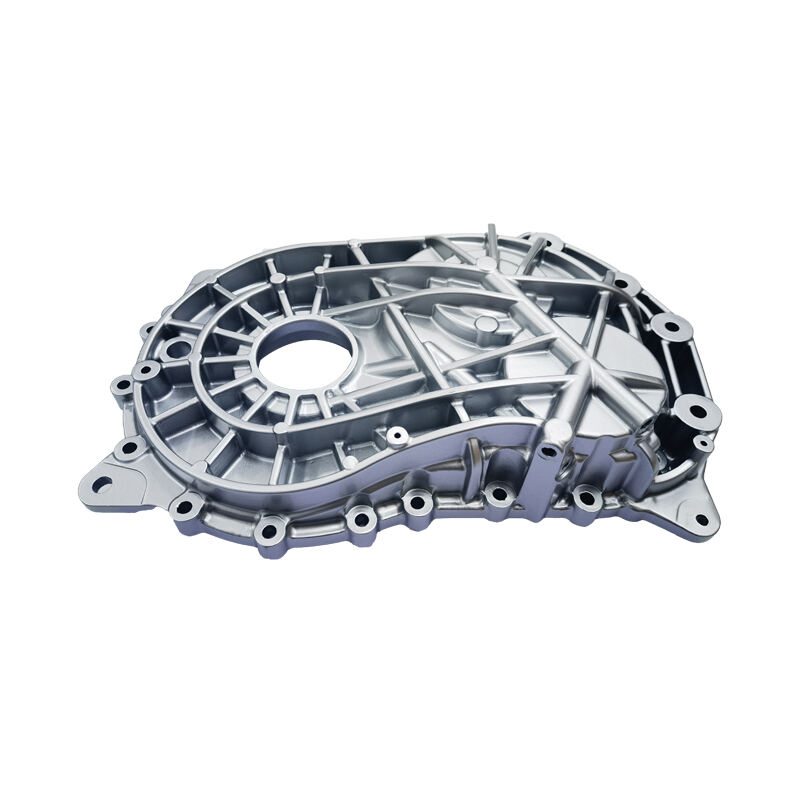

In SLM 3D printing, a laser is employed to fragment the metal powders and stratum by stratum assemble the features shaped with those powders. It allows the manufacturing of complex parts, within which light weight features are highly integrated and cannot be easily achieved using conventional machining. To the automotive sector, this means the production of complex designs that will improve the performance of components while maintaining their beauty.

One of the main advantages of SLM 3D printing in machinery and automotive engineering is fabrication of very lightweight and durable parts. Weight reduction of the vehicle’s components is particularly important and can lead to enhanced performance in terms of fuel economy. SLM 3D printing technology enables the fabrication of parts with light but stronger designs which in essence are called load optimized elements WHALE STONE 3D’s SLM 3D print service gives automotive designers these possibilities.

Furthermore, SLM 3D printing brings forth personalization and swift 3D printing. The technology supports developing different concepts and changing existing ones during the design, which makes it very easy for automotive designers to test out new concepts and make design changes quickly. This makes the entire process quicker and veneer design innovation out in the market sooner. SLM 3D printing service from WHALE STONE 3D specified for rapid prototyping enables car manufacturers to keep the competitiveness.

SLM 3D printing corresponds with such principles as higher material efficiency and economic expediency. Most of course manufacturing techniques incorporate subtracting techniques which translates to a tremendous loss of materials. On the other hand, SLM 3D printing doesn’t work that way, it takes metallic powders and output directly the resultant parts which decrease the waste and maximize the usage of materials. This not only cuts down the production cost but also promotes environmentally friendly manufacturing.

Also, the scope of SLM 3D printing covers other processes and materials as well. Automotive parts must have certain properties like strength, resistance to corrosion, and heat and many other. WHALE STONE 3D has brought into the market diverse arrays of metal powders such as stainless steel, aluminum, and titanium considering the needs in automobile industry.

To conclude, WHALE STONE 3D’s SLM 3D print service features professionalism and brings changes to the automotive industry by providing advanced manufacturing techniques. SLM 3D printing is one of the most valuable points for automotive innovation in modern times, being able to produce lightweight and high-strength components, promote rapid prototyping, and improve material utilization.