When discussing modern-day applications in the manufacturing industry, high precision as well as reliability is required for the production of any components. In WHALE STONE 3D, we have an exceptional ability to provide exceptional CNC machining services to meet even the highest requirements. Hench, the cutting-edge technology alongside the skilled professionals makes it possible for the completion of each and every order to be on point regardless of its’ magnitude.

An Overview of the CNC Machining Method

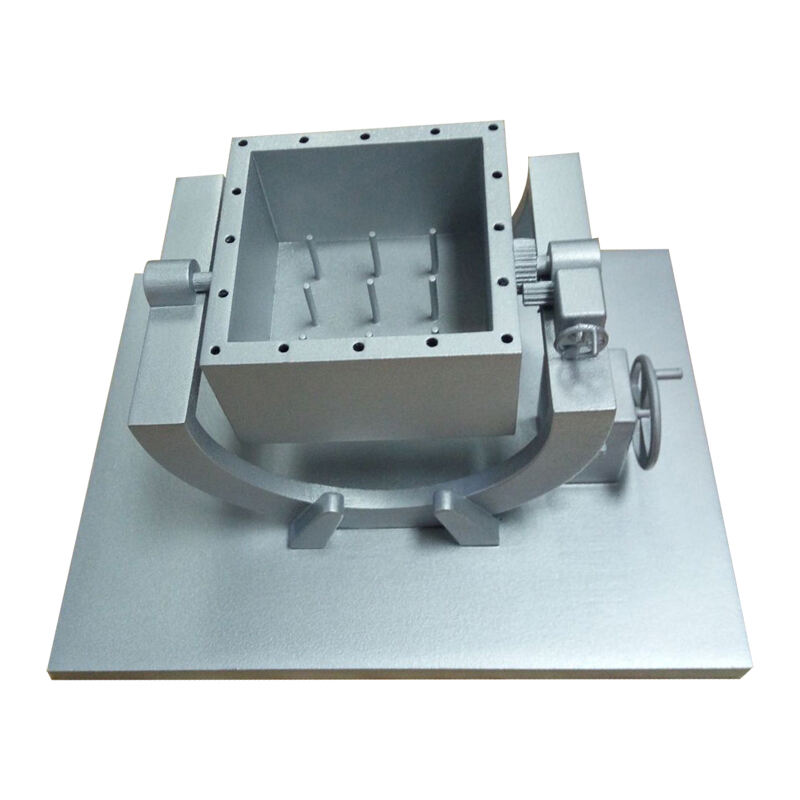

CNC (Computer Numerical Control) machining is a modern method of manufacturing where machines tools are operated by computers. This method is normally used for precise cutting, drilling and shaping various materials including metals, plastics and composites. WHALE STONE 3D has adopted the CNC technology in its production processes and therefore we are able to construct intricate parts with good consistency and low chances of defects.

Why Working with WHALE STONE 3D Makes Sense?

Advanced Technology: WHALE STONE 3D MAKES USE OF A TREAT TOPOGRAPHY IN ORDER TO ACCURATELY ACQUIRE THREE DIMENSIONAL VIRTUAL PHOTOGRAPHY OF OBJECTS, they offer CNC machining services with superior levels of accuracy and flexibility through the use of the most cutting edge CNC machines. These comprise of multi axis CNC millers and turners as well as routers that have sophisticated software for intricate mathematics and intricate engineering designs.

Expert Team: They are experienced in carrying out CNC machining hence are able to handle even the most difficult projects. This guarantees that each and every part made will be conforming to acceptable standards including the toughness and shape.

Custom Solutions: Each project is unique; hence, there is a need for every project to have a bespoke service. In WHALE STONE 3D, you can order the precise CNC machining services that you need: whether it is modeling, limited series, or mass production.

Applications of CNC Machining

CNC machining is employed in different industries such as aerospace, automobile, medical and consumer products. The services offered by WHALE STONE 3D support applications like:

Aerospace Components: Approved aerospace grade and the quality control associated with it, including reliability, increases, and external parts of the aircraft and spacecraft.

Medical Devices: Tools and implants are offered-safety and integration of use are the focal points while designing and producing custom parts.

Automotive Parts: Quality and performance remain optimal for high-quality automotive components manufactured for vehicles with outstanding performance.

Consumer Products: Parts of the common market products where mildew and precision create value additive.

Quality Assurance

WHALE STONE 3D carries out all its tasks with high quality. A strict adherence to quality assurance is required and followed at each stage of production. We keep our CNC machines dot-head calibrated and also we make every effort for the most thorough control over all parts manufactured with modern measuring devices.

Conclusion

WHILE STONE 3D offers CNC machining services which are the most sophisticated and accurate in all industrial production, nevertheless, we are able to deliver better_result which exactly meets your requirements. Contact us today and find out just how our CNC machining services will help realize your project more effectively and accurately than you ever thought possible.