Custom Silicone Mold Plastic Rapid Prototyping 3D Model Making with Urethane ABS Vacuum Casting Machining Services

- Overview

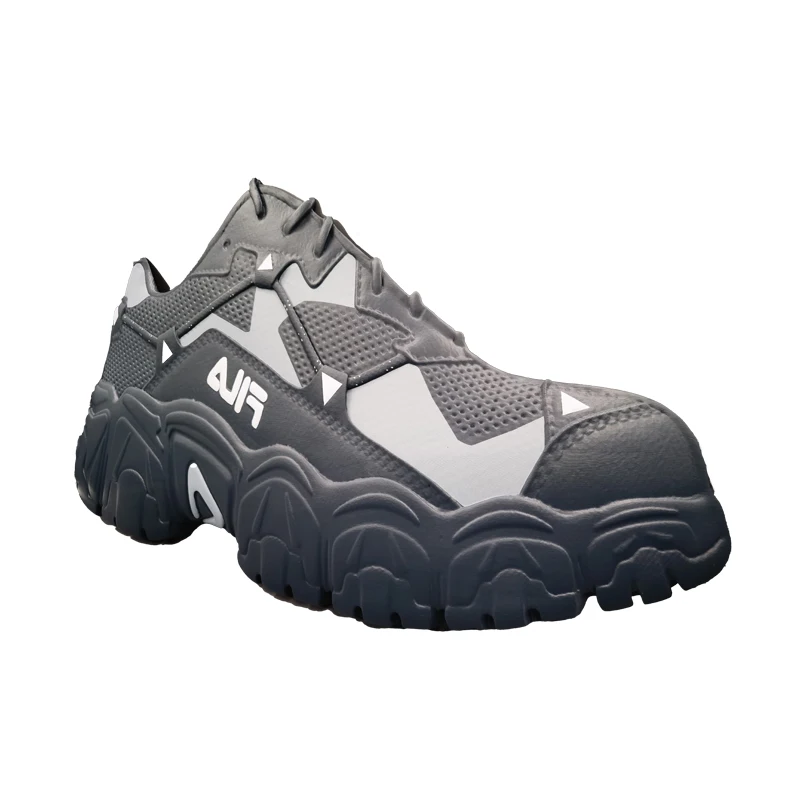

- Related Products

Material selection:

Silicone mold: Flexible, suitable for complex shape replication, durable and reusable.

Polyurethane: Provides excellent wear resistance and strength, suitable for functional prototypes.

ABS plastic: Lightweight, strong, widely used in product prototypes and consumer products.

Technical advantages:

Vacuum Casting: Efficient production of small batch parts, smooth surface and fine details.

Machining: Precise processing, suitable for parts with strict requirements on size and tolerance.

Application areas

Product design: Used to quickly verify design concepts and shorten product development cycles.

Automotive industry: Make parts and models to support rapid prototyping and testing.

Electronics: Produce housings and components to ensure functionality and beauty.

Item |

Value |

CNC Machining or Not |

Not CNC Machining |

Type |

Rapid Prototyping |

Material Capabilities |

Nylon ABS PC PP POM Acrylic etc |

Micro Machining or Not |

Micro Machining |

Place of Origin

|

China |

Model Number |

WhALE-STONE Vacuum casting |

Brand Name |

WhALE-STONE |

Product name |

vacuum casting plastic parts |

Surface treatment |

painting,polish,burring |

MOQ |

Small Orders Accepted |

OEM/ODM |

Accecpted |

Color |

Customized Color |

Logo |

Accept Custom Logo |

Size |

Customized Sizes Acceptable |