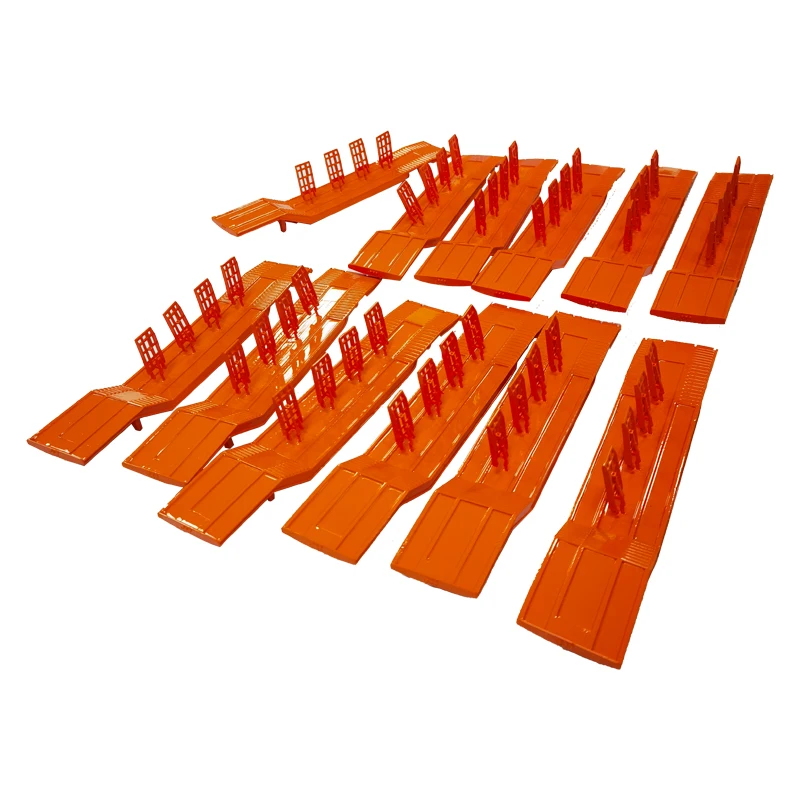

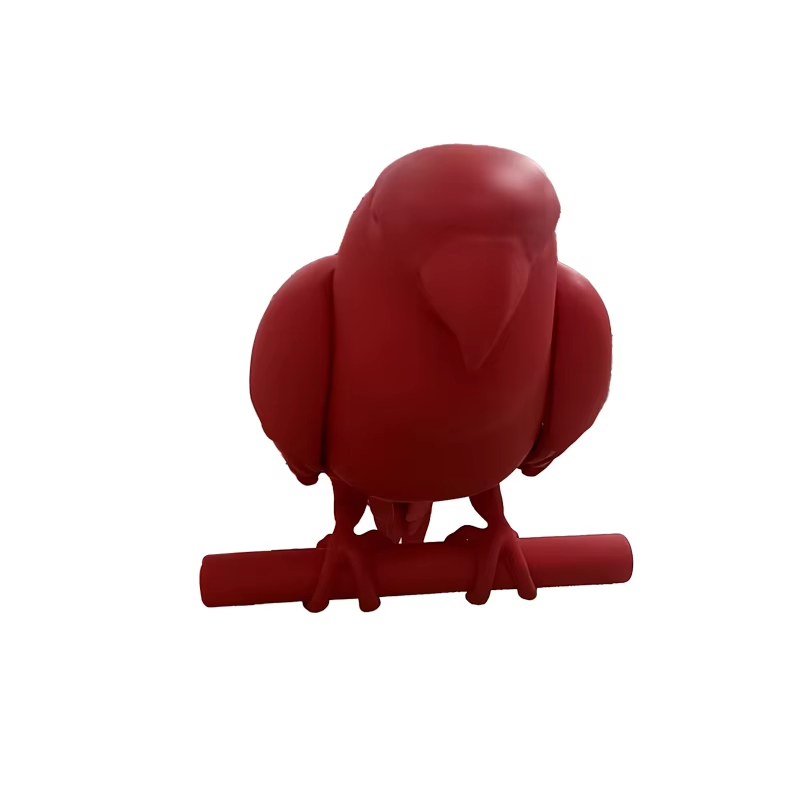

Custom Resin 3D Print Service High-Strength Materials Robust SLA Rapid Prototyping Resin 3D Printing Products

This service meets customers' needs for high-strength and high-durability 3D printed products. By using advanced SLA technology and high-quality resin materials, we are able to quickly produce 3D printed prototypes or products that meet customers' specific requirements.

- Overview

- Related Products

Product Description

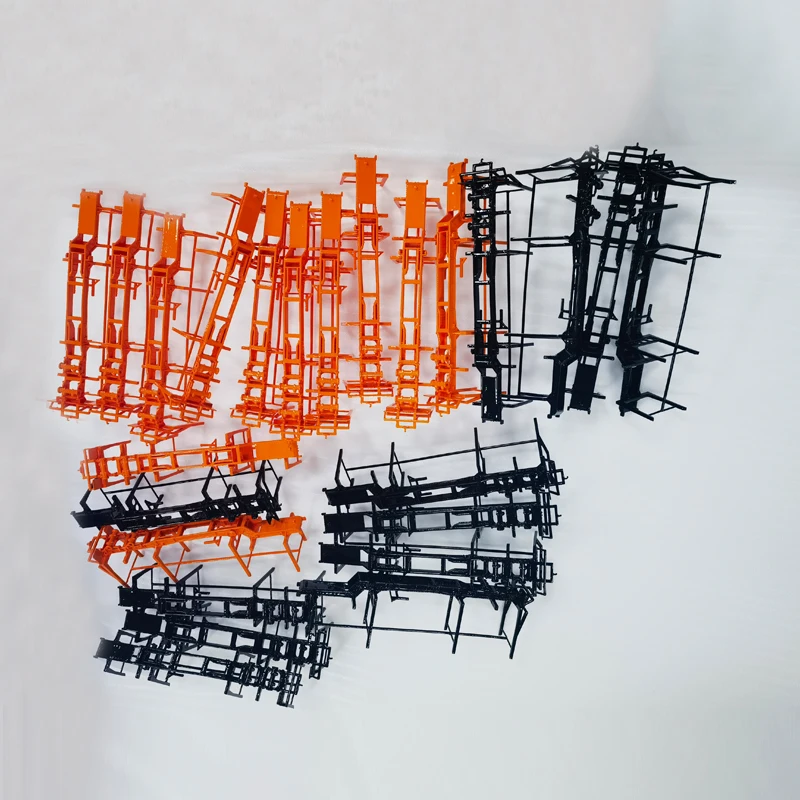

Customized service:

Provide personalized 3D printing solutions according to the specific needs of customers.

Customers can freely choose parameters such as materials, colors, sizes, etc. to meet their specific application scenarios.

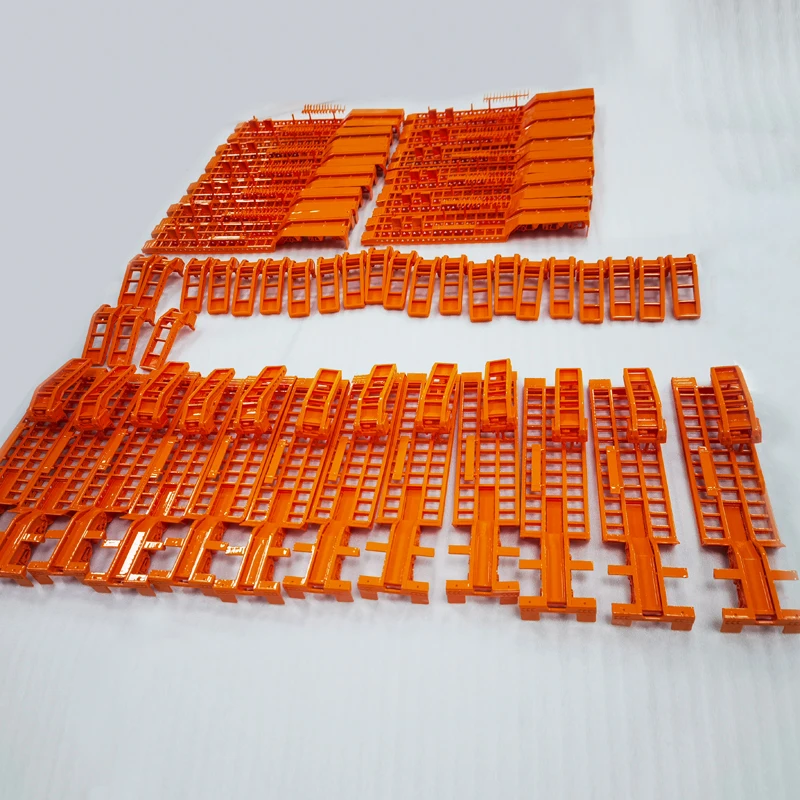

High-precision printing:

SLA technology has the characteristics of high precision and can print 3D products with rich details and complex structures.

The surface of the printed product is smooth and flat, without too much post-processing.

High-strength material:

The resin material used has high strength and toughness and can withstand large forces and pressures.

It is suitable for 3D printed products that need to withstand certain loads or withstand environmental influences, such as automotive parts, aerospace parts, etc.

Rapid prototyping:

SLA technology has the characteristics of fast printing, which can greatly shorten the product development cycle.

Customers can obtain the required 3D printed prototypes in a short time for subsequent design verification and testing.

Perfect post-processing:

Provide perfect post-processing services, including cleaning, removal of support structures, polishing and coloring, etc.

Ensure that the printed products meet the customer's quality requirements and meet their specific application scenarios.

Transparent and reasonable prices:

Provide a clear price system, and customers can choose according to their own needs and budget.

Reasonable and transparent prices ensure that customers will not incur excessive costs while receiving high-quality services.

Provide personalized 3D printing solutions according to the specific needs of customers.

Customers can freely choose parameters such as materials, colors, sizes, etc. to meet their specific application scenarios.

High-precision printing:

SLA technology has the characteristics of high precision and can print 3D products with rich details and complex structures.

The surface of the printed product is smooth and flat, without too much post-processing.

High-strength material:

The resin material used has high strength and toughness and can withstand large forces and pressures.

It is suitable for 3D printed products that need to withstand certain loads or withstand environmental influences, such as automotive parts, aerospace parts, etc.

Rapid prototyping:

SLA technology has the characteristics of fast printing, which can greatly shorten the product development cycle.

Customers can obtain the required 3D printed prototypes in a short time for subsequent design verification and testing.

Perfect post-processing:

Provide perfect post-processing services, including cleaning, removal of support structures, polishing and coloring, etc.

Ensure that the printed products meet the customer's quality requirements and meet their specific application scenarios.

Transparent and reasonable prices:

Provide a clear price system, and customers can choose according to their own needs and budget.

Reasonable and transparent prices ensure that customers will not incur excessive costs while receiving high-quality services.

Application areas

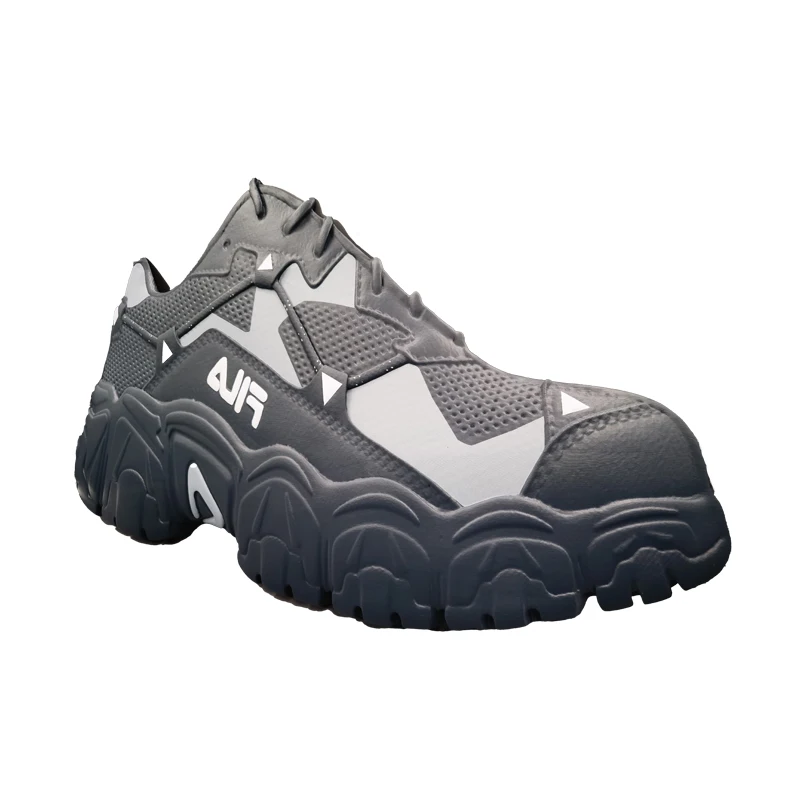

Product development: In the product development stage, SLA technology can be used to quickly make prototypes to help designers and engineers verify the feasibility and functionality of product designs.

Automobile manufacturing: The automotive manufacturing field requires various parts with complex structures. SLA technology can produce high-precision and high-strength resin parts to meet the needs.

Aerospace: The aerospace field has extremely high requirements for the precision and quality of parts. SLA technology can print out resin parts that meet the requirements.

Medical field: The medical field requires a variety of customized, high-precision medical devices and parts. SLA technology can print out resin products that meet the requirements.

Product development: In the product development stage, SLA technology can be used to quickly make prototypes to help designers and engineers verify the feasibility and functionality of product designs.

Automobile manufacturing: The automotive manufacturing field requires various parts with complex structures. SLA technology can produce high-precision and high-strength resin parts to meet the needs.

Aerospace: The aerospace field has extremely high requirements for the precision and quality of parts. SLA technology can print out resin parts that meet the requirements.

Medical field: The medical field requires a variety of customized, high-precision medical devices and parts. SLA technology can print out resin products that meet the requirements.

Specification

item |

value |

Place of Origin |

China |

CNC Machining or Not |

Not CNC Machining |

Material Capabilities |

Resin |

Type |

Laser Machining, Rapid Prototyping |

Micro Machining or Not |

Micro Machining |

Model Number |

SLA |

Brand Name |

WHALE-STONE 3D |

Color |

White Brown Transparent Yellow etc. |

Feature |

High Precision, Fast Delivery and Cheap Price |

Size |

Customized Sizes Acceptable |

Surface treatment |

Customer's Request |

Process |

Painting |

Equipment |

SLA 3D Printer |

Service |

Cutomized |

Keyword |

3D Rapid Prototyping |

Logo |

Accept Custom Logo |